SEEIF Ceramic

SEEIF Ceramic, a.s. develope and produce ceramic gating systems (ceramic holloware), which is formed by refractory shapes with high resistance to penetration by molten metal and is intended for single use in casting systems assemblies during the metal casting. As well produce ceramic closing systems for foundry and steel ladles, standard refractory shapes, insulating materials and many other refractory products for use in steel and iron foundries. We offer full advice on the matter

Ceramic gating system

Upgraded refractory casting bricks with high resistance to the penetration by molten metal.

Ceramic components for closings of casting ladles

Refractory fittings which form a part of the closing system of casting ladles.

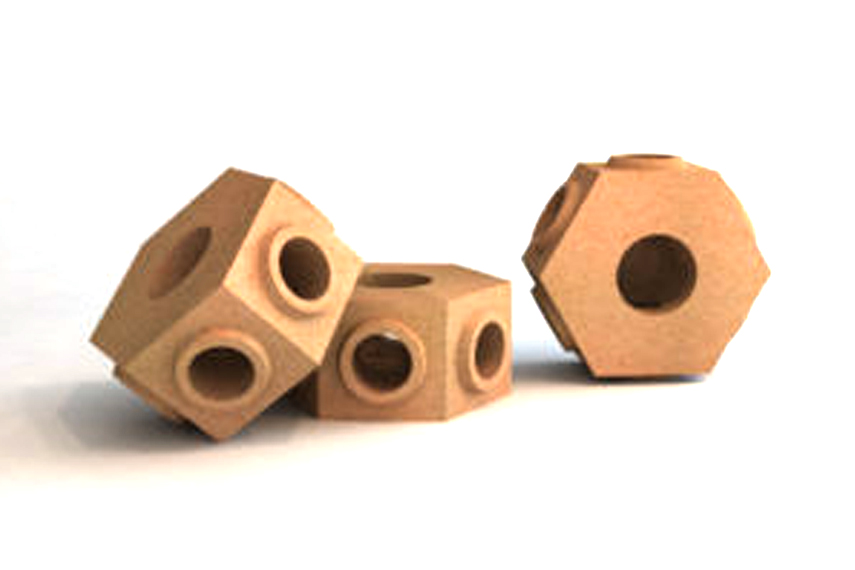

Ceramic Whirl Gate

The ceramic whirl gates, so called slag traps, are widely used mainly in steel and ductile cast iron foundries.

Ceramic Whirl Gate For Foundries

The ceramic whirl gates, so called slag traps, are widely used mainly in steel and ductile cast iron foundries. These parts of gating systems are operated on the principle of different volume density of melt, slag and others impurities. The whirl gates are installed in the casting routes. The molten metal from the casting route is thrown inside the vessel. During this rotational motion particles float towards the melt surface on the principle of different densities. Calm and cleaned metal is led through the distribution channels into the mould.- absorbs the primary melt shock and calms the flow by converting the turbulent flow into the laminar one

- filters small and large impurities and the major part of drawn air

- eliminates defects caused by human error in case of low technological discipline

- is large enough to catch even higher volumes of impurities

- in case of ladles with sliding closures catches filler particles

- does not create secondary inclusions

- metal does not “freeze” due to bad heat capacity

- guarantees stable flow (compared with the filters, the whirl gate cannot be clogged)

- does not slow metal flow rate

Available in several sizes depending on the diameter of the ceramic casting system.

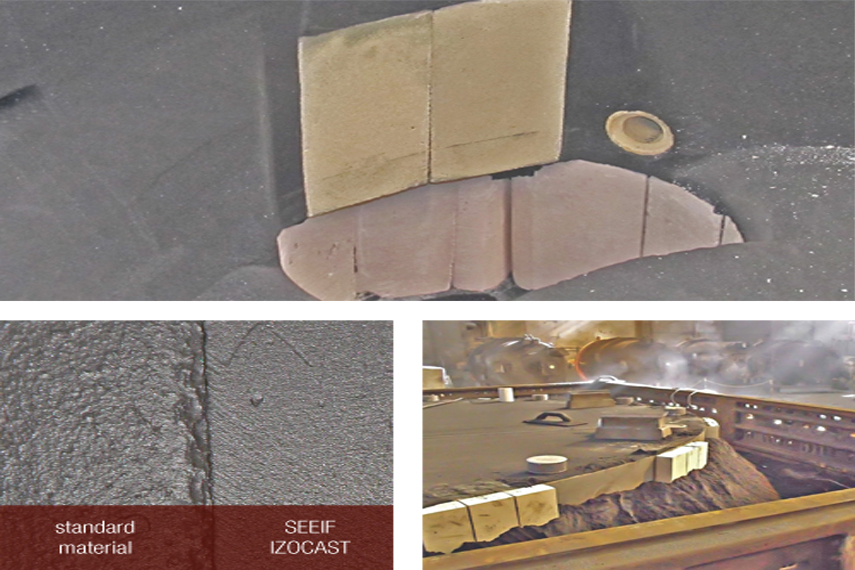

Insulation Izocast

Two-layer insulating shapes of the “sandwich” design are used in foundries, where it is necessary to increase the metal feeding distance of certain casting places or to extend the solidification time. The blocks are primarily placed on areas where is necessary to extend solidification time without compromising quality of the surface – we are speaking about the areas that will not be machined any more or that require only a small allowance for machining.- EXTENSION OF SOLIDIFICATION TIME – increase of the metal feeding distance in the necessary points of the casting.

- WITHOUT ADDITIONAL MACHINING – thanks to a special working layer the places, where the IZOCAST products are applied, do not need to be machined any more and cleaned after removal.

- EASY WORKABILITY – the blocks can be cut easily and shaped directly on the spot to particular requested dimensions.

Izospar – Insulation Of Risers In Foundries

Izospar products are refractory heat-insulating standard squares and shapes with low bulk density.

Izospar products are used as a heat insulation of risers in foundries for more economic use of the molten metal, reduce labor intensity in the molds making (lower tops of the forms), reduce the area of burned risers, offer more efficient use of pads under risers and also reduce cost of risers (sufficient is production of necks for cases). Flow of the riser must be treated by exo-dusting with expandable graphite.

Propetries:

|

Bulk density

|

600-800 kg/m3 |

|

Cold crushing strength

|

min. 1 MPa |

|

Refractoriness

|

min. 1 730 °C |

|

Insulation coefficient

|

fiz 1,45 |

Casting Fireclay

Single use fireclay products for foundries and steelworks fits as the assembly of ceramic gating system during the iron casting. They are suitable for castings from 5 kg up to hundreds tons and are characterised by increased resistance against a penetration by molten metal.

Foundry holloware production range consists of funnels, tubes, adapters (reductions), elbows, T & L pieces, crevices, splash cores and other specialty shapes with inner diametres from 30 mm up to 150 mm.

Shapes are available in several grades according to the Al2O3 content.

|

Quality properties

|

F36

|

ML65

|

|

Al

2O

3

|

36 %

|

65 %

|

|

Fe

2O

3

|

2,5 %

|

2,5 %

|

|

Refractoriness

|

1 700 °C

|

1 780 °C

|

|

Funnels - Different types of funnels with various diameters, shapes and sizes, with possible banding. |

|

Special pipes - Various types of pipes for the centre brick connection. |

|

Kingbrick - Center bricks - Manually or mechanically formed kingbricks for dividing the casting stream with one or more outlet openings, in various diameters and sizes. |

|

Through channels and end channels - Mechanically pressed “through channels“ in various diameters and lengths. The shape of the channels depends on the casting plate. We make “through channels“, with one or more outlet openings on different sides of the channel. We make wide sortiment of end channels. |

|

"Kokilnik" - For outflow steel casting, you can use our special product called “kokilnik“, formed from a single piece. |

|

Ingot risers - To connect the inlet to the ingot mold, we manufacture several types and various sizes of ingot risers. |

If you have any questions regarding our services, please contact us or call at +91 70252 22888.