- sales@thorngate.in

- +91 98703 36345

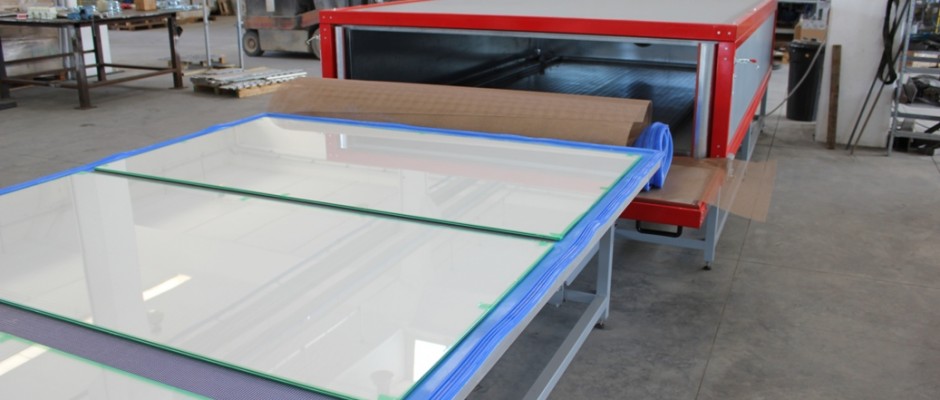

Machine for laminating flat glass with EVA. The oven consists of a heating chamber where the housing is provided for a plane or a multi-storey system for increased production.The glass loading and unloading system works by extracting the plane of an outer rail or through the use of a hydraulic platform for the multi-storey system.An integral part of the system is an oil vacuum pump, connected to the silicone bag on the plane, by means of high temperature resistant silicone tubing and related attachments to make the vacuum required for the lamination of glass.

Inside the heating chamber, the thermal cycle occurs through a hot air convection system which distributes the heat evenly throughout the chamber and across the surface of the glass. The glass loading and unloading system works by extracting individual planes using a hydraulic platform.

An oil vacuum pump, connected to silicone bags at each individual plane, by means of high temperature resistant silicone tubing and related attachments to create the vacuum required for the lamination of glass Hot air convection system which distributes the heat evenly throughout the chamber and across the surface of the glass.

The machine will be installed at your site by our technicians.

The technicians provide training of your staff for a proper use and maintenance of the plant .

© 2018 thornGate