- sales@thorngate.in

- +91 98703 36345

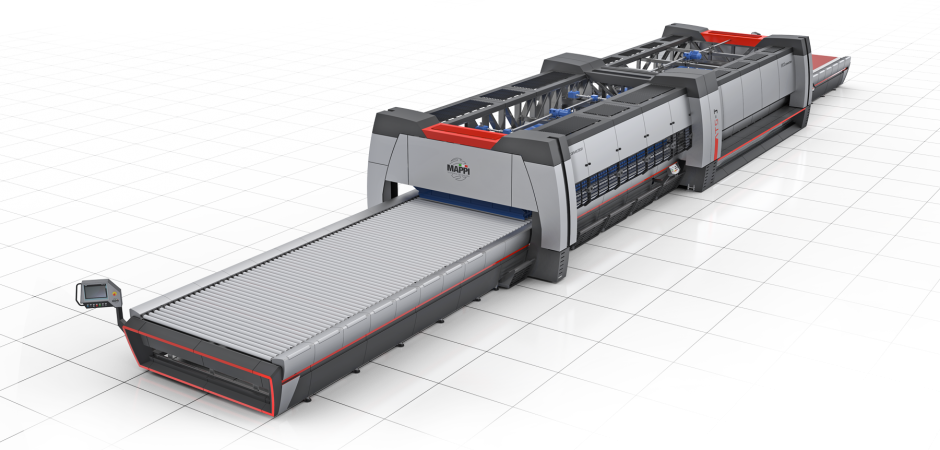

All the power you need, when you need it

ATS 4.0 raises the bar in limiting consumptions through the use of coordinated MHS, ESS and ATI systems, a Mappi exclusive. ATS 4.0 raises the bar in productivity because it minimizes the time between tempering cycles, until you approach a virtually continuous cycle without down time for the adjustment of the operating temperatures.

—

All the precision you want, up to perfection

Glass is an honest material, unable to hide its strengths and weaknesses. Any imperfections in flatness, each optical distortion undermines the value, especially in the case of the most modern productions, such as laminated or the Low Emission. ATS 4.0 reduces to the minimum values now possible all glass defects due to the computer management of the movement, the heating and air temperatures for tempering, supported by the use of engines and materials of absolute excellence.

—

GHBS Xtreme Profile Convection System: the heart and the mind of ATS 4.0

The “heart” of a furnace for tempering is in its ability to produce heat, but this is nothing if it is not accompanied by a clear and reactive “mind”, which manages in the best way both the heat and the air flows on the glass, its functional qualities, consumption and productivity of the system. A tempering furnace with exceptional performances as ATS 4.0 has an extraordinary heart. GHBS Xtreme Profile Convection System allows you to:

• Process all the type of lowE glasses

• Reduce cycle time and increase productivity

• Manage distribution of air separately in lower and upper heating chamber

• Modulate the pressure of the air in single areas

Intelligent modules for heat diffusion ATS 4.0 handles the heat through intelligent of only 300x600mm modules. Each of these is governed by a network of electronically controlled sensors. This makes stable the temperature and minimizes power consumption.

Ceramic rollers The glass movement is ensured by an extra quality ceramic roller system, the best solution for duration, thermal efficiency, fluidity of movement.

Brushless motors The movement of the rollers is ensured by the high precision “brushless” type motors. This helps to ensure to the glass you will produce the optical characteristics typical of Mappi furnace excellence.

MHS (Multizone Heating System) It automatically manages through intelligent modules the temperature of the furnace through a network of electronically controlled sensors. In this way it remains constant and focused only in areas where there is the presence of glass.

ESS (Energy Saving System) Heating and forced ventilation stages are coordinated and managed by a computerized system optimizing fuel consumption and allows to significantly reduce the installed power required by the entire system.

IHS (Intelligent Heating System) The internal temperature of the furnace is controlled with an accuracy of +/- 1’C: this prevents overheating of the moving rollers and avoids downtime for the adaptation of the furnace temperature.

SYNCHRO (Room’s Rolls Movement System) The patented system which allows the perfectly synchronized movement of the ceramic rollers on which the glass flows. The system avoids the use of sulfur dioxide in the heating process.

ATI (Active Thermal Insulation) fully reduces thermal dispersion, a success due to a continue research on the materials, in collaboration with the most prestigious research centers in Europe.

SH (Smart Heating) appears from the cooperation with Gefran and Kantal, an even more precise new system of resistances capable of maintaining the unbeatable 300 x 600 mm form, it succeeds to increase the thermal efficiency thanks to the new materials exclusive developed for Mappi, all of this is controlled by new static relays that allows a modulation of the energy never seen before.

AC (Advanced Cooling), an original design for the blowing system allows an even more precise control while tempering. It substantially decreases the iridescence of the glass.

TOUCH (Integrated Touch System) The system monitors in real time the parameters of the tempering process, it immediately prints the compliance report for CE and ANSI glass standard, it automatically stores each production cycle.

TAB SYSTEM The system allows the tempering furnace operator to provide real-time technical assistance through a dedicated tablet interface.

© 2018 thornGate