- sales@thorngate.in

- +91 98703 36345

★ OPTIMISED FOR SPECIAL GLASS ★ DEVELOPED WITH LEADING GLASSWORKS ★ HIGH QUALITY STANDARDS

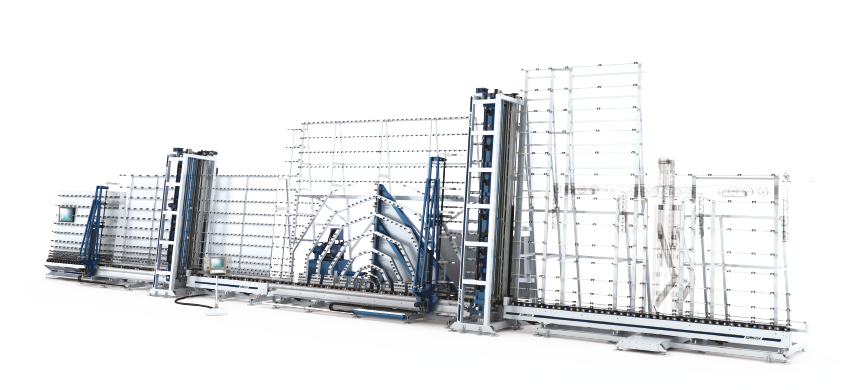

The VC02 vertical laminate cutting line fulfills the ever increasing demand for cut to size laminate GLASSES via its unique and highly patented system. Throughout the entire process the laminated glass sheet is kept vertical minimizing glass handling whilst maximizing productivity and due to its vertical nature the machines footprint is kept to a minimum operated by just one person.

The VC02 is complemented by Forel’s ST6006 automatic glass storage and management system which allows the operator to automatically and safely control the stock and cutting phases. Forel’s AL6002 is an automatic glass sheet loading device that allows for the continuous supply of glass sheets to the cutting line avoiding any unnecessary interruptions to production. The machine is equipped with two independent cutting bridges intersected by a glass sheet turning station that allows for Jumbo sheets to be processed. Enhanced optimization is achieved via X,Y and Z axes cutting. Each of the cutting bridges comprises of two opposing carriages that cut the front and backside of the glass sheet simultaneously. Two breakout bars split the cut down its whole length in a uniform way avoiding shelling, cracks or any other imperfections. Specifically designed dual resister infrared lamps soften the PVB interlayer without heating the glass for automatic glass separation. A patented motorized ironing system separates the two glass sheets allowing for a blade to cut the film. The bridges can be equipped with automatic edge deletion for the removal of low emissive coatings. Optimal cutting is ensured by software which rearranges the information in order to make the operation quicker and easier for the operator. Cutting information can be manually inserted directly to the touch screen control unit. The unloading area can be equipped with Forel’s TT2503 tilting table. This facilitates the manual breakout of small trim and off cuts. The machine is equipped with a self-diagnostic system that identifies faults with codes, descriptions and images with an additional system that allows for remote connection and assistance.

© 2018 thornGate