- sales@thorngate.in

- +91 98703 36345

★ OPTIMISED FOR SPECIAL GLASS ★ DEVELOPED WITH LEADING GLASSWORKS ★ HIGH QUALITY STANDARDS

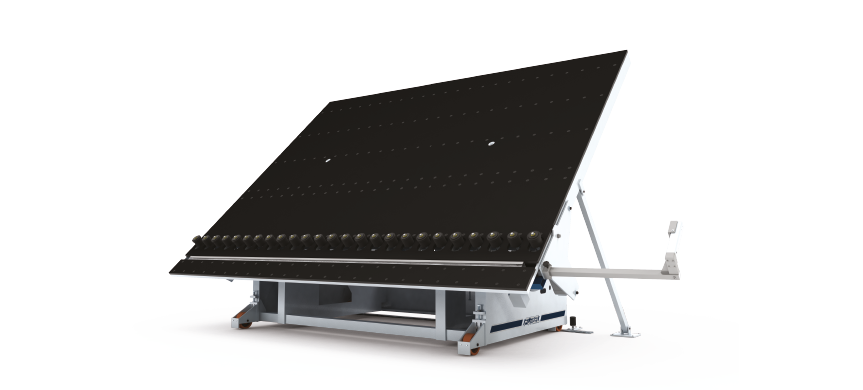

The TT2503 tilting table offers complete “functionality” for the laminated glass cutting line, ensuring safe handling of glass sheets requiring manual cutting or removal operations. The main feature of TT2503 is to tilt the glass from the vertical to the horizontal position with the aim of allowing the operator to safely process the presented glass sheet. A “balanced tilting” movement rotates the glass sheet while moving the bottom edge forward by means of special rollers installed on the bedplate. This presents the glass edge conveniently close to the operator. The handling of the glass sheet on the work surface is made easy by the installed electric fan driven air flotation system. This allows safe and easy positioning of all glass sheet sizes and thicknesses. Once the sheet has been tilted to the horizontal position (pre-scored by the laminated glass cutting line), the operator can perform the manual separation of the off-cut via the radiation heat lamp mounted on the front (lower edge) of the tilt table. This lamp is used to heat the PVB membrane to allow easy separation and splitting.

© 2018 thornGate